Packing

Professional Packing

Deliver your goods to you in good condition

Packing for Bed

Packaging for Chairs

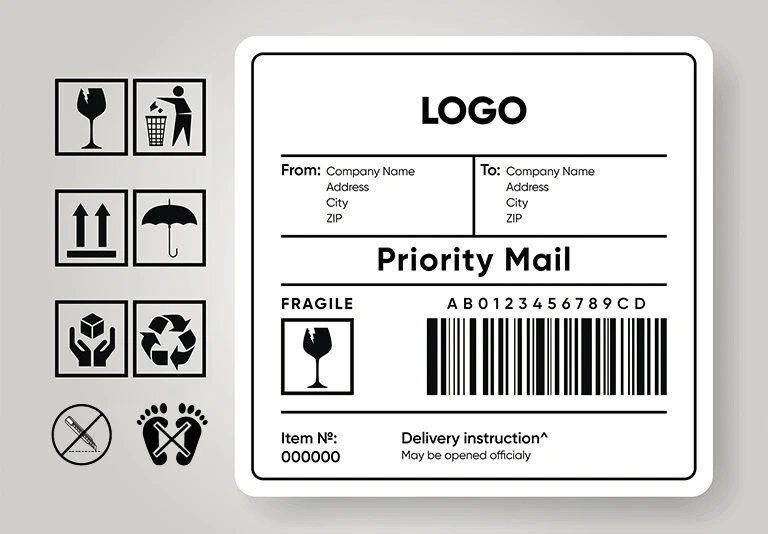

The size of logo should be adjusted to place the correct position according to the size of carton and always on the upper left hand side corner.

Carton Printing

Warning Mark(On main marking side)

- This way up arrow is to follow according to the Flutes of the Carton!

- Warning mark;

- For items 25kgs above with “team lift”;

- Production with glass parts.

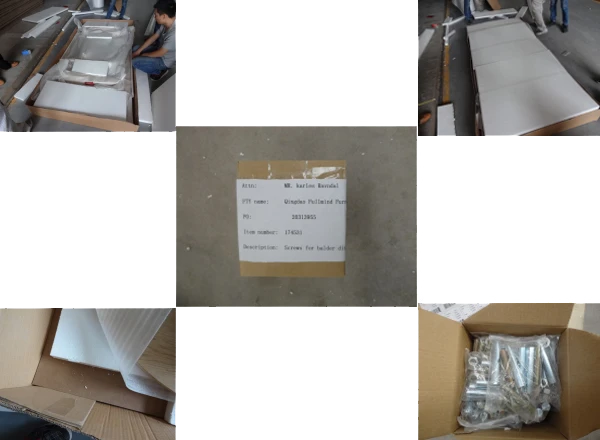

Main Marking

- Logo;

- Item Number;

- Warning mark;

- Description & Colour&Overall size;

- Qty;

- Carton;

- PO No;

Side Marking

- Logo;

- Item Number;

- Qty;

- PO No;

- G.W;

- N.W;

- Meas;

Barcode

- Barcode Sticker Should Be Stick On The Lower Right Corner of Both 1 Main Marking And 1 Side Marking Is A Must

- Item No. XXXXXX should be printed on barcode. EAN 13

- Qty,PO No,G.W,N.W,Meas;

Assembly instruction

- A/I need to be approve before print.

- All accessories/components/parts/panels should be marked by letter sticker.And all should be matched with the assembly steps on AI.

- All hardware fittings should be packed by polybag separetely kind by kind and maked by letter, then put all polybags to a small box.

- All screws/bolts should be with size listed.

Packing Method

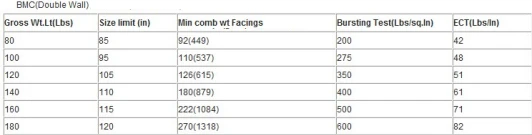

Carton

- Carton burst strength must be minimum 200lbs(Should be with the certificate mark on top)

- Brown colour carton with MARTINSEN logo.

- With barcode - should be printed and pasted on carton.

- Double Wall Corrugated Carton (5 Layer Brown Carton)

Poly foam

- All corner edge must have polyfoam and corrugate board coner pad.

- 4 sides and top must be covered with polyfoam.

- All legs of dining tables must be packed by PE foam and well fixed in the production.

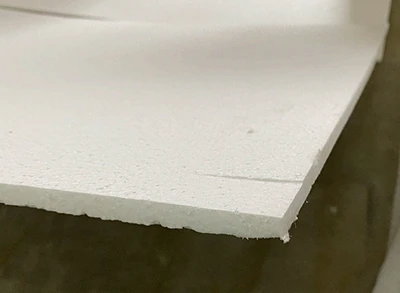

Bottom support

- For Cabinet, Casegoods or any product with standing Legs,the legs should be K.D and packed separetely. If not,there must have a bottom panel support.

- *The bottom panel support shoud be with inner carton size. A plywood with minimum 5mmT or A well glue skate board with center brace.

- No applicable for table.

Corner Pad

- hardboard corner pad + Polyfoam (16KG)

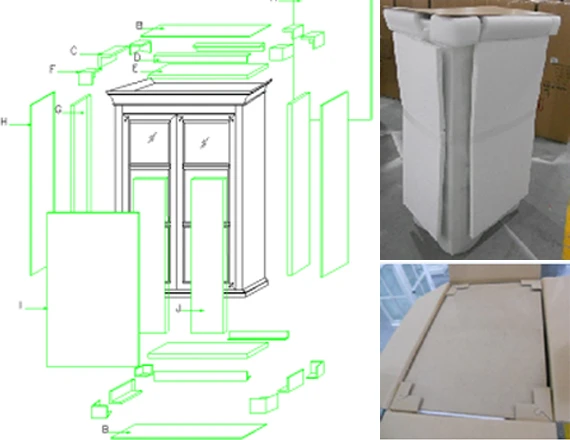

Packing Step for cabinet

- Side and top of products should be covered with Polyfoam.

- Goods should be covered with layer of PE foam.

- Corner pad / block should be applied.

- Edge should be covered with corrugated roll or carton paper.

- Warp with plastic film.

- Bottom support should be added for the products more than 1200mm.

- Pack into carton - try to push the carton, must feel solid and no overhang allowed.

A: 2.5cm polyfoam.

B: 3mm MDF

C/D: Edge protector.

E: Polyfoam

F: Corner protector.

G: Polyfoam.

H: 2.5cm Polyfoam.

I: 2.5cm Polyfoam.

J: Polyfoam.

Packing step for table

- Master carton no less than 200 lbs/in2 burst, Double Wall Corrugated Carton--5 Layer Brown Carton.

- Wrap each component with bubble bag or PE sheet.

- Coner protectors needed(2cm thick).

- Add protective kraft cardboard on the seam to avoid from cutting product when open using blade.

- Top and bottom covered by 2cm polyfoam.

- Bottom use 3mm MDF under the 2cm polyfoam

Spare Parts Packing

- Spare Parts by FOC for each shipment (3%)

- Pack in separate box and proper labelling

- Spare Parts for speical PO by customer request because of quality problem

- Pack in separate box and proper labelling

Raw Mat & Hware

- Frame: Solid wood. According to specification by buyer or agreed by buyer.

-

Side & Top Panel:

MDF with Veneer for the normal smooth & clean (stain or glaze) finishing.

Plaint MDF for White or black pigment colour -

Table Top:

MDF with Veneer for the normal smooth & clean (stain or glaze) finishing

Plaint MDF for White or black pigment colour -

MDF with Veneer:

European E1 Class standard

Both size should have a veneer. 2nd grade venner is allow for the bottom side BUT general weight must be the same as top surface. -

Finishing:

AC (Acid Curing) or PU (Polyurethane) coating for smooth & clean finishing.

NC (Nitrocellulose) can be use in brushing or sandblasting finishing. -

Back Panel:

For products like TV unit, Sideboard, Display unit.

6mm MDF veneer or Plywood,applicable on set up and KD product -

MC content:

Acacia & Rubber wood below 8%~12%

Poplar below 8%~12%

Pine below 8%~12%

Elm below 8%

Oak below 8%

-

Full extension slide

All Drawer's need to have full extension slide -

Soft closing hinges

All Door's have to be soft closing -

Tempered Glass

Min 5mm Tempered glass for all shelves and Table top(with Tempered Glass Mark)

-

Anti-tip kit

To any Cabinet / Casegoods will need to have anti-tip kits. -

Connect panels

For those cabinets with Buffet and Hutch must be with metal connect panel -

Tempered Glass

Min 5mm Tempered glass for all shelves and Table top(with Tempered Glass Mark) -

Adjustable glide with counter sunk flush

For those Cabinet / Casegoods which has Door's and Drawers at all legs.. -

Spring washer

Any Bolt that securing to the Insert nut must have spring washer. -

Washing Label

Any cushion cover which is removable must have washing Label -

F.O.C spare parts

A 3% spare parts have to be included for every shipment.

We support custom packaging

We have a variety of packaging services and packaging solutions, to ensure the safety of the transportation of goods, you can also provide your packaging requirements and specifications to us, we support OEM and ODM, for your goods escort

Packaging Design

The packaging types of furniture products, namely, ceiling type cardboard boxes, counter type cardboard boxes, and side sealed cardboard boxes. Board corner protectors must be added inside the cardboard box to prevent the nails from scratching the product. The corner protectors are made of three layers of cardboard. The size of the cardboard box depends on the size of the product. The calculation method is to add the length, width, height, and padding thickness of the packaging product, generally leaving a width margin of 25mm~30mm.

At present, the internationally commonly used classification method for corrugated boxes and cardboard boxes is proposed by the FEFCO European Hardboard Box Manufacturing Association (ASSCO), which is called 0201 type box in the international cardboard box type standard.

Green packaging

Furniture green packaging emphasizes the environmental protection requirements of furniture packaging while meeting the requirements of protecting furniture products and facilitating transportation.

(1) The packaging of furniture should achieve reduced design, save raw materials, reduce packaging costs, and also reduce environmental pollution;

(2) When selecting the packaging materials used, materials that can be reused or recycled should be selected. Corrugated cardboard boxes, honeycomb cardboard, PE foam, and other materials can all be recycled and reused;

(3) Alternatively, biodegradable plastic packaging materials can be chosen as they can be buried in the soil after disposal and do not cause environmental pollution.